Project

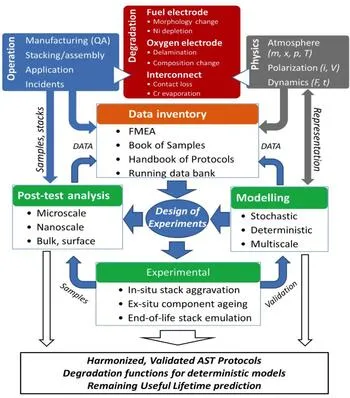

AD ASTRA stands for 'HArnessing Degradation mechanisms to prescribe Accelerated Stress Tests (AST) for the Realization of SOC lifetime prediction Algorithms'. We will approach the challenge of developing AST protocols according to the scheme below

Let’s look at this from top to bottom.

Degradation: the critical issues focused on – in fuel cell/electrolysis modes – are:

- fuel (negative) electrode: microstructural evolution such as nickel agglomeration (densification), nickel depletion (volatilization) in both modes; delamination in SOEC and reoxidation in SOFC mode

- oxygen (positive) electrode: material decomposition and reactivity with the electrolyte, delamination (in both modes), electrode microcracking due to composition changes in SOEC mode and chromium poisoning in SOFC mode

- interconnect: contact loss, especially at the oxygen electrode side, due to long-term thermal oxidation and degradation of coating properties (both in electrolysis and fuel cell modes), solid state diffusion in the contacting layers, including the sealing.

Manufacturing and atmosphere:

Failure modes are governed by macroscopic inputs such as the variance in component manufacturing or stack assembly, operating conditions and potential incidents. These causes manifest themselves in the stack through the physical quantities of mass (m), gas composition (x), pressure (p), temperature distribution (T), electrochemical polarization (i, V), mechanical force (F) and the dynamics of their changes (t).

Data inventory:

In order to analyse the correlation between these operational dimensions, a structured data inventory is necessary, where all formats of information regarding the specific stack components (post-operation images, performance figures, sample history) can be accessed for efficient comparison, interpretation and use. The analysis of data is the hub of the project, where previous knowledge (regarding material behaviour, performance assessment, degradation models etc.) will be structured, in order to design experimental campaigns focusing on filling crucial gaps in data as well as correlate post-operation states with in-service. The accumulated experience in ENDURANCE [link to: http://www.durablepower.eu/] will be used, where a “Handbook of Test Procedures and Protocols” (open access deliverable) with data available in the literature and project results was prepared.

Experimentation and modelling:

With a systematic inventory conceived, dedicated work can be carried out in experimentation (through in-situ stack aggravation and ex-situ component ageing), post-test analysis (selecting field-tested and aged samples for structural and chemical mapping) and modelling (developing stochastic models for the integration of degradation functions into mechanistic models). This approach allows for the unique opportunity to identify both common and different dependencies in SOFC & SOEC.

Harmonized, validated Accelerated Stress Test Protocols:

Feeding back the outcomes of the specialized tasks into the data inventory will lead to an iterative production of accelerated stress test protocols validated by long-term field operation as well as specifically tested and simulated SOC behaviour. The specific protocols, as well as the optimized methodology for identifying